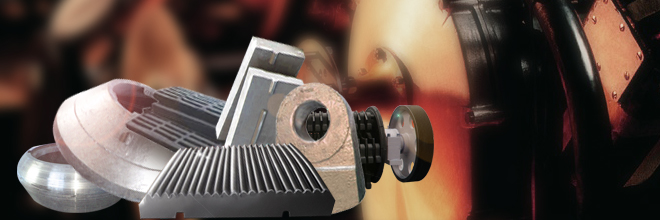

Double roll crusher for sale in coal mining

*Double roll crusher for sale with cheap price (lower cost) in coal mining. Double roll crusher daily operation and maintenance can be professionally supplied by We experts based on 15 years’experience on mining equipment research and development double

4.9

(6238 Ratings) 8560 views and hit

4.9

(6238 Ratings) 8560 views and hit

Double roll crusher for sale with cheap price (lower cost) in coal mining. Double roll crusher daily operation and maintenance can be professionally supplied by YIHONG experts based on 15 years’experience on mining equipment research and development. Double roll crusher is suitable for crushing medium hardness materials in the cement, chemical, electric power, metallurgy, building materials, refractories and other industrial sectors, such as limestone, slag, coke, coal and other materials in the debris, crushing operations.

Double roll crusher daily operation and maintenance

First, when the double roll crusher, requirements rod valve completely opened up, so that the feed inlet the roller face all uniform force; bypassed feed requirements rod valves all closed, paying particular Note that the prevent unsocial crusher material into the crusher roller room; materials all broken after it stopped crusher or crusher not boot up properly.

Second, for the double roll crusher, we should clear separator scrap, and put an end due to clear the double roll crusher card of the scrap metal leaving dead.

Third, for the double roll crusher, material card dead double roll crusher, loosen the adjustment screw, active roll back, the two roller gap to increase, making the material come to nothing. Note that the reset to return to the original position. Can’t be forced to jog the motor, so that the passage of materials in order to avoid damage to the motor and other equipment.

Fourth, as for double roll crusher, the requirements of each class to be on a roll crusher bearing lubrication, the clinker temperature and weather temperature changes, appropriate adjustments to the number of refueling and the amount of fuel.

Fifth, the double roll crusher roller room side inspection door, 2-3d cement mill pressure load time check again, whether chunk of foreign matter and to view two roller surface wear. Chunk of foreign matter to deal with in a timely manner, the roll surface wear to heap electrode wear (open the case front and back doors can repair welding) in a timely manner, with special bolts fastening roll skin in a timely manner, and prevent roll move.

Sixth, double roll crusher of the crushing opportunity to non-magnetic metal enter or loose bolts and other unusual circumstances, cause considerable vibration crusher must be an emergency stop. Of course we have to take electrical general protection.

Seventh, double roll crusher should ensure that the stock roll paper set (welding electrode wear), a set of drive V-belt, roll leather oval bolt 20 sets of hardfacing electrodes 20kg, main bearing set, homemade the bolt socket wrench set, and the number kinds of different thickness to adjust steel bars.

Tag : double roll crusher for sale,coal double roll crusher,coal mining roll crusher

- Crusher Wear Parts

- Jaw Plate

- Crusher Hammers

- Liner Plate

- Cone Concave

- Impact Crusher Blow Bars

- Grate Plate

- Crusher Rotor

- Crusher Roller

- Crusher Spare Parts

- Jaw Crusher Parts

- Cone Crusher Parts

- Stone Crusher Parts

- Rock Crusher Parts

- Impact Crusher Parts

- Hammer Crusher Parts

- VSI Crusher Parts

- Gyratory Crusher Parts

- Grinding Mill Parts