Double roll crusher crushing efficiency improve

*Double roll crusher crushing efficiency improve methods can be offered by We professionals. Double roll crusher is the use of two separate sets of drive rollers, the relative rotation of the extrusion rolling force and grinding shear to crush materials

4.9

(8906 Ratings) 12005 views and hit

4.9

(8906 Ratings) 12005 views and hit

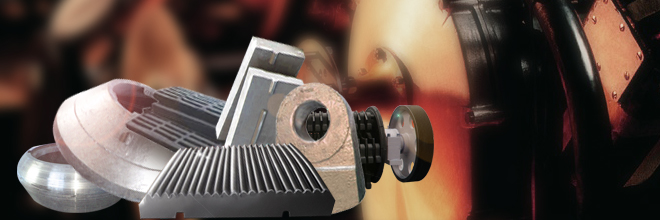

Double roll crusher crushing efficiency improve methods can be offered by YIHONG professionals. Double roll crusher is the use of two separate sets of drive rollers, the relative rotation of the extrusion rolling force and grinding shear to crush materials.

Double roll crusher working principle

Double roll crusher working principle is as followings: When the materials enter the crushing chamber of the machine after the material by force, rotating roller shaft material forced between two rollers, at the same time by the roller shaft extrusion rolling and shear grinding material fragmentation, fragmentation small particles along the tangent of the roller rotation, through the gap of the two roller axis, is thrown to the bottom of the machine, over a gap large particulate material, to continue to be broken into small particles discharged.

Double roll crusher crushing efficiency improve methods

Double roll crusher crushing efficiency improve methods can be offered by YIHONG, and you can take the following measures:

First, a reasonable choice of double roll crusher models and the control of the diameter of the feed. Generally, the diameter of the double roll crusher roller should be not less than 9 times before the clay particle size in the crushing, i.e., D ≥ 9R, in order to obtain a good crushing effect.

Second, control the moisture content of the mud. The rate of the water content of the mud should not be too high, and should generally be controlled at 15% or less, otherwise the formation of clay in the influence of the crushing efficiency and crushing effect.

Third, the feed should be uniform. Not suddenly feeding excessive mud is preferably the entire width of the roller can fall in order to reduce uneven wear of the roller. Fourth, recess to maintain the proper roller gap. Two roller gap should be maintained between 3 ~ 5mm gap is too large to be promptly repaired or replaced, otherwise influencing the crushing efficiency.

Fifth, double roller system process if necessary, ie, two double roll crusher for primary crushing and crushing, and fully guarantee the quality of crushing.

Double roll crusher applications

Double roll crusher applications are fairly wide. It is available for processing, chemical, cement, refractories, abrasives, building materials and other industrial sectors, crushing high hardness ores, rocks and refractory materials. Double roll crusher can achieve superior mechanical effect especially than the common crushing machines in refractories and mining industry. In recent years, it is widely used in crushing grit and other industries.

Tag : Double roll crusher,Double roll crusher crushing,roll crusher crushing efficiency

- Crusher Wear Parts

- Jaw Plate

- Crusher Hammers

- Liner Plate

- Cone Concave

- Impact Crusher Blow Bars

- Grate Plate

- Crusher Rotor

- Crusher Roller

- Crusher Spare Parts

- Jaw Crusher Parts

- Cone Crusher Parts

- Stone Crusher Parts

- Rock Crusher Parts

- Impact Crusher Parts

- Hammer Crusher Parts

- VSI Crusher Parts

- Gyratory Crusher Parts

- Grinding Mill Parts