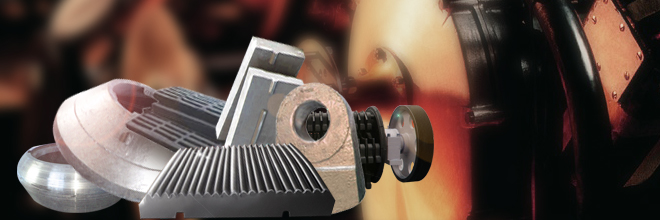

Manganese steel hammers,high manganese steel crusher hammers

*We know crusher hammer that are the wear parts of hammer crusher, so crusher hammers need to be regularly replaced. We hammers are the manganese steel hammers and high manganese steel crusher hammers. We have applied a patent for the crusher hammers

4.9

(7658 Ratings) 8623 views and hit

4.9

(7658 Ratings) 8623 views and hit

We know crusher hammer that are the wear parts of hammer crusher, so crusher hammers need to be regularly replaced. YIHONG hammers are the manganese steel hammers and high manganese steel crusher hammers. We have applied a patent for the crusher hammers and named by Big Gold Teeth™, it is like a gold generally indestructible. You use our manganese steel hammers, you will get more profits for your company.

Manganese steel hammers advantage

1. A good overall performance, high reliability;

2. Wear resistance, good safety performance and excellent value for money;

3. Especially suitable for high silicon content, strong abrasive limestone and break poor, anti-wear, high efficacy, long service period;

4. High manganese steel, wear-resistant hammerhead secondary refining and overall pressure casting technology, more pure, more dense matrix of molten steel, the crusher hammer life 50-100% increase compared to the ordinary high-manganese steel hammer, the use of more safe and reliable.

Manganese steel hammers make process

1. High manganese steel wear hammerhead technical production of inlaid wear-resistant alloy, cast-intensive extremely tough on the traditional hammer high manganese steel matrix, tungsten titanium alloy hardness second only to diamond, can resist harsh abrasive wear;

2. Optimize the heat treatment process, water toughening treatment;

3. Alloying method to optimize the matching chemical composition, the use of rare earth modification, niobium and vanadium precious elements strengthening the matrix; vacuum casting, directional solidification technology, grain refinement greatly simply eliminate casting defects;

4. Strict production management, advanced casting process and machining processes. Every aspect of our production has a 24-hour camera surveillance, the factory must pass through the laboratory quality control section stringent sampling layers of monitoring to ensure the quality of every batch of hammerhead;

5. Wear-resistant high manganese hammerhead was added during the casting process, such as molybdenum, vanadium, titanium, chromium, nickel, boron, more noble alloy elements and variety of alloys Modificator processing, strengthening the matrix.

Our crusher hammers customer, As follows

1. JianXI, China - DongShui cement plants, recording up to 17 months using times;

2. HeNan, China - TianRui cement plants, increase 30% in service life than ordinary hammer, highly praised by the leadership of the group;

3. OEM - YIHONG provide High manganese steel hammer for your major crusher manufacturers the customized processing business, no matter what type of hammer, drawings or samples, the Company will be able to produce.

Tag : Manganese steel hammers,high manganese steel crusher hammers,manganese steel crusher hammers

- Crusher Wear Parts

- Jaw Plate

- Crusher Hammers

- Liner Plate

- Cone Concave

- Impact Crusher Blow Bars

- Grate Plate

- Crusher Rotor

- Crusher Roller

- Crusher Spare Parts

- Jaw Crusher Parts

- Cone Crusher Parts

- Stone Crusher Parts

- Rock Crusher Parts

- Impact Crusher Parts

- Hammer Crusher Parts

- VSI Crusher Parts

- Gyratory Crusher Parts

- Grinding Mill Parts